We offer manufacturers in the automotive, lighting technology, medical technology, aerospace, control technology, and electrical engineering sectors customized and individual solutions for their applications.

All thermal management products are also manufactured as customer-specific parts. A range of manufacturing technologies are available to enable us to respond flexibly to customer requirements.

In addition to films and sheets, we offer you the option of purchasing other thermal management products such as silicone hoses or caps.

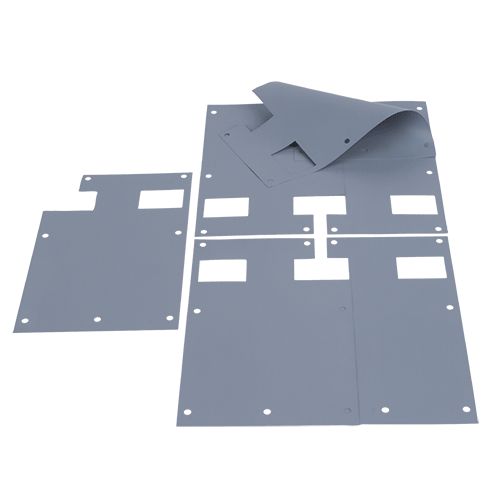

Thanks to our wide range of processing options (services), we have been able to meet even the most difficult customer requirements in the form of custom-designed parts.

Please contact us if you require silicone-free thermal management products (pads).

Heat conducting foils and heat conducting pads - DETAKTHERM

DETAKTA specializes in high-quality and innovative insulating materials for industry and, in addition to various insulating, heat-shrink and fabric sleeves, also offers high-quality heat-conducting products such as heat-conducting film and heat pads. The constantly growing product range includes a large number of silicone-based products in various designs. The main differences lie in the area of thermal conductivity (from 1.0 to 7.0 W/mK) as well as dielectric strength and individual requirements in terms of the finish, such as adhesive, adhesive or fabric-reinforced.

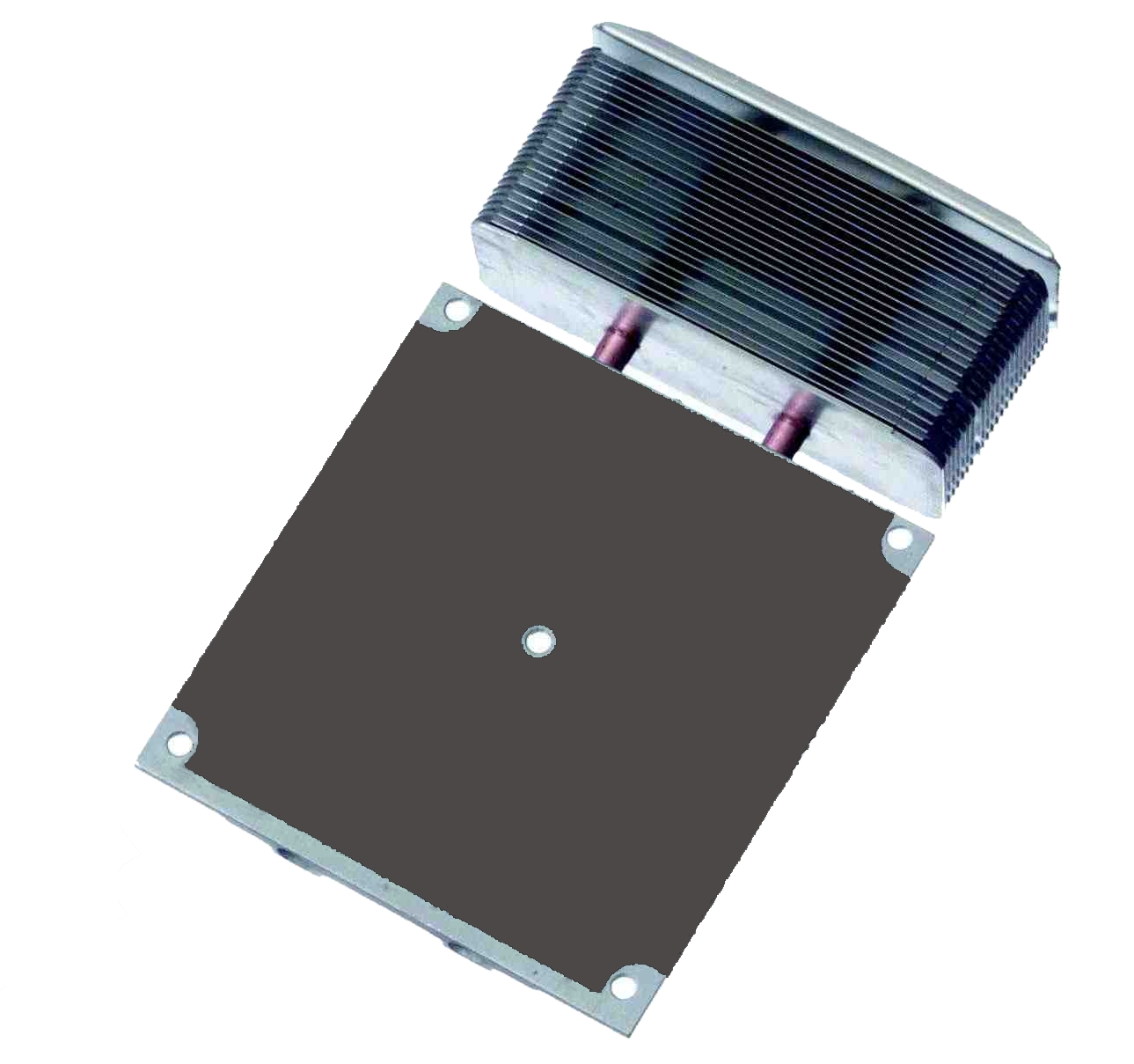

Use of thermally conductive foilsHeat conducting foils and gap pads improve heat dissipation and enable efficient heat transfer between two surfaces. In order to avoid temperature-related failures in electronic systems, thermal conductive materials are used to compensate for the component differences between the electronic components and heat sinks in the best possible way and to ensure optimum cooling of the electrical system.

As neither the surface of the electronic component to be cooled nor the heat sink are absolutely flat, there is air between the two surfaces, which hinders heat equalization. For this reason, a heat-conducting material, such as a film, is placed between the elements or a heat-conducting pad is used for larger distances.

Application areas and industries in which thermally conductive films are used

Efficient heat transfer and dissipation is required in many different areas.

In addition, thermal conductive films are also used in the aerospace and medical technology industries to achieve reliable temperature regulation.

Heat conducting films and heat conducting pads - also available as self-adhesive

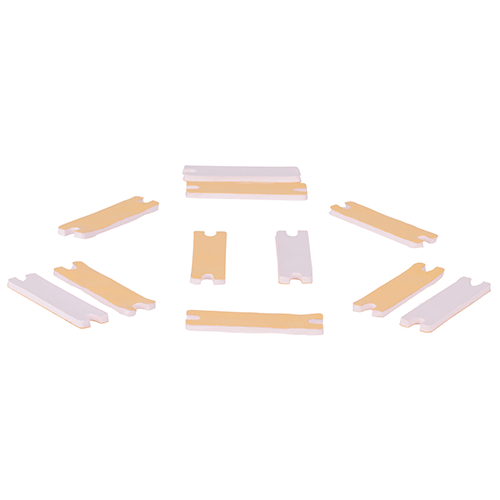

With our range of silicone heat conducting foils and pads, you will find the right product for every application. Thanks to their high elastic adaptability, heat sources and heat sinks can be optimally connected. Our heat conducting films are also available as self-adhesive or double-sided adhesive on request.

Silicone glass fabric from the SB-HIS series: thermal conductivity value 1.0 to 5.0 W/mKHeat-conducting, insulating silicone elastomer with a glass fabric insert. It is suitable for installation on smooth surfaces. The material is non-adhesive, but the thermally conductive film can be made self-adhesive, double-sided adhesive or single-sided adhesive on request. The films in the SB-HIS series are available as roll material from a thickness of 0.15 mm up to 0.8 mm.

Silicone soft pads from the SBC series: thermal conductivity value 1.0 to 7.0 W/mK

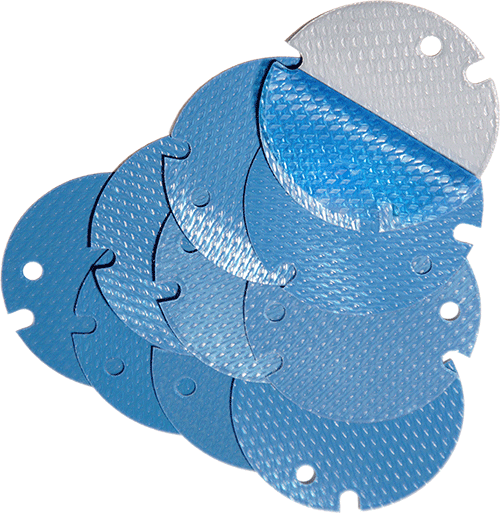

The gap pads in this series consist of a thermally conductive, insulating silicone elastomer with very good elastic adaptability. Due to the low hardness, a very good fit is achieved even with low contact pressure, even with irregular shapes. The heat conducting foil is equipped with a double-sided adhesive surface. The SBC models include unreinforced and gel-shaped mats in various thicknesses from 0.5 mm to 5 mm.

Silicone glass fabric pads - the SB-V0 models: Thermal conductivity value 1.3 to 7.0 W/mKFor applications that are subject to particularly high mechanical stress or require a very soft film, we have developed the pads in the SB-V0 series. Like the unreinforced SBC types, these have been modified and provided with a glass fabric on one side. This reinforcement enables very soft films such as SB-V0YF or mechanically highly resilient types such as SB-V0. These heat conducting films are adhesive on one side and are available in thicknesses from 0.5 mm.

Further information on the individual films and pads in our range can also be found in the respective data sheets, which are available for download.

Heat conducting film for special requirements: our special solutionsOur portfolio also includes special solutions that meet specific requirements, such as high thermal conductivity or dielectric strength. Combinations of different films are also possible.

On request, we can produce thermally conductive films (self-adhesive, single-sided and double-sided adhesive) according to your individual requirements. Simply contact us and let us know your requirements for thermally conductive films or pads. We would be happy to advise you in a personal meeting - make an appointment now by email info@detakta.de or by phone on 040/529547-0. We will implement the right solution for you!What are heat conducting foils?

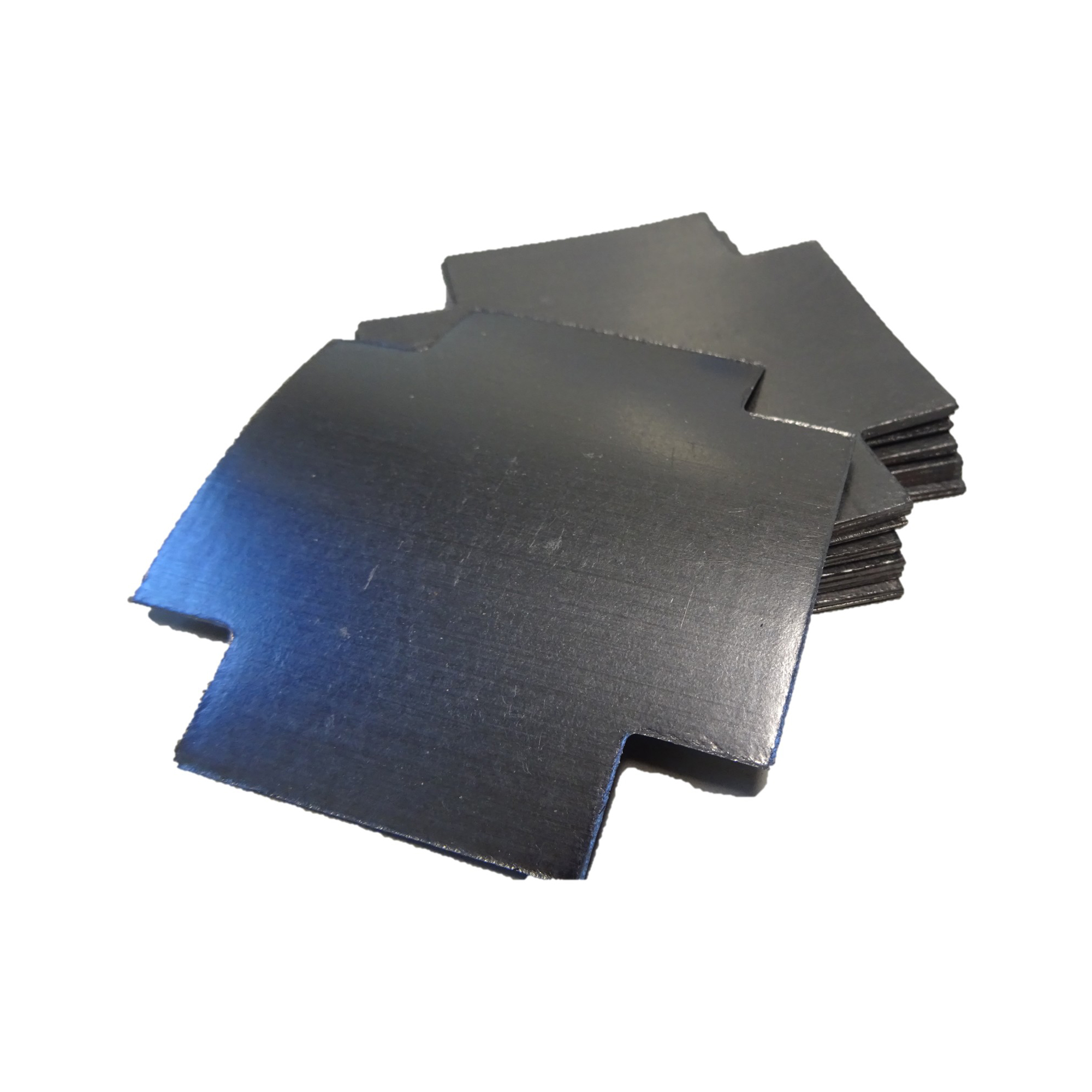

Heat conducting films are thin, flexible films with high thermal conductivity. They are ideal for efficiently transferring heat from one surface to another and dissipating it from power components in electronic applications. Heat conducting foils can be made of silicone or graphite, for example - these materials minimize thermal resistance, which optimizes heat dissipation. In this way, the overheating of power components and devices can be prevented, thereby extending their service life and increasing their energy efficiency.

What are thermal conductive films made of?To ensure optimum heat dissipation, heat conducting films are made of flexible materials with high thermal conductivity. Materials such as silicone with fillers such as aluminum oxide, boron nitride or graphite are frequently used.

How do thermally conductive foils work?The functionality of thermally conductive foils is based on their high thermal conductivity. When placed between two surfaces, they form a heat-conducting layer that enables efficient heat transfer to the heat sink. It is crucial that heat conducting films adapt perfectly to the contact surfaces of the hot and cool elements. The films should therefore be particularly flexible and thin.

Heat conducting films from DETAKTA: customer-specific production also possible

In addition to first-class quality, you can rely on on-time delivery from DETAKTA. Thanks to our extensive warehousing, we can deliver most of the desired products within 24 hours. In addition, we offer all our thermally conductive products to manufacturers in the automotive, medical technology, aerospace, control technology and electrical engineering sectors, providing customized and individual solutions for their applications, for example customer-specific production according to drawings. In order to meet the different customer requirements and to be able to react flexibly, we have access to a wide range of manufacturing options. Parts can be punched, processed using a cutting plotter or cut into the finest contours using a water jet.

Are you interested in a specific heat conducting film or heat pad and have questions about its technical properties? Our DETAKTA team has a wealth of knowledge and experience. Benefit from this expertise and get in touch with us. We will be happy to help you personally and advise you individually. Just get in touch with us!DETAKTA: Your experts in insulation technology

We specialize in the sale of innovative insulation materials for industrial applications and offer our customers in the mechanical and electrical engineering sectors an extensive product portfolio. Are

you interested in our products or would you like expert advice? We are happy to assist you with our know-how and many years of experience. Contact us by email at info(at)detakta(dot)de or by phone at 040/529547-0.

We look forward to hearing from you!