In addition to the expert advice provided by our sales staff, in recent years we have focused on offering services that enable us to realize

customer-specific product designs.Particularly noteworthy here are the various processing methods for flexible insulating materials (such as Mylar A, Hostaphan RN, and polyimide) and our extensive range of thermal interface materials.

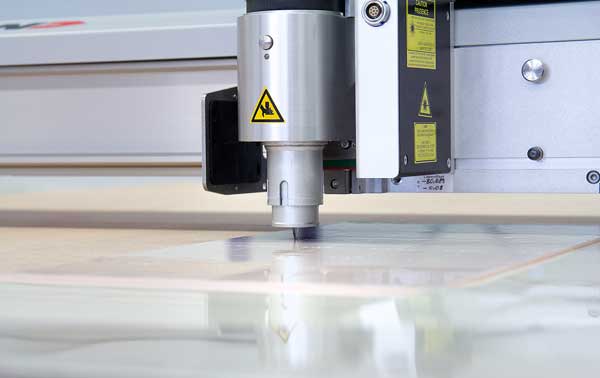

Depending on the complexity and volume, the following processes are used:

Our many years of experience in using these methods form the basis for consistently uniform and flawless execution to meet customer requirements.

In the segment of insulating, protective, and heat-shrink tubing, other services are naturally required, mainly relating to assembly and printing. In this case, we offer two processes, which are selected in consultation with the customer depending on the desired color scheme, print image, and volume.

These are inkjet printing and thermal transfer printing.

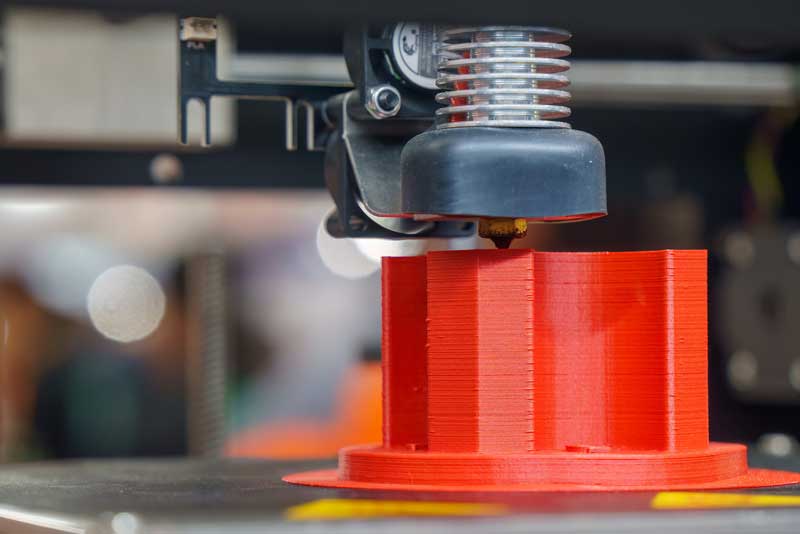

For prototype construction or small one-off quantities of components made from PA12 or silicone, we offer you the option of using 3D printing processes. All

we need from you is a 3D CAD file in stp format.

If you also require an EMPB (initial sample test report), we will be happy to provide this at a charge based on the work involved.

DETAKTA: Your experts in insulation technology

We specialize in the sale of innovative insulation materials for industrial applications and offer our customers in the mechanical and electrical engineering sectors an extensive product portfolio. Are

you interested in our products or would you like expert advice? We are happy to assist you with our know-how and many years of experience. Contact us by email at info(at)detakta(dot)de or by phone at 040/529547-0.

We look forward to hearing from you!